That musty, moldy basement smell that we have come to accept as unavoidable, is actually quite avoidable. The solution is really quite simple - stop building below grade with walls that were designed for above grade and your basement won't smell like old gym socks and potentially make you ill with mold spores.

As a freshly poured concrete foundation will take 5 years to fully dry it's hardly surprising many go moldy, and this is hoping that measures have been taken to ensure it is completely protected from ground moisture ingress by waterproof membranes on every single surface. Concrete is like a sponge, and when left unchecked will continue to wick moisture from the ground and distribute it into your home for as long as your home stands, especially if the relative humidity and natural (air leakage) ventilation in the home means that ground floor rooms are less humid than the basement. All that ground moisture will be continually sucked into the concrete and will then often cause fungus and mold issues in your batt insulation, timber frame or drywall. And frankly, that sucks!

So why are basements moldy and damp?

1) The National Building Code now insists on basement insulation (this is a good thing), and it needs to be done before delivery to homeowners, which will be years before the concrete in the basement walls has fully dried.

2) Decisions on wall assemblies and the materials that will be used are most often made based on initial building costs, not future repair costs, energy performance or protecting the health of occupants by mitigating mold formation. They most certainly are not based on the laws of physics,that is the one thing we know for sure.

3) The cheapest way to insulate a basement is on the inside, and using finishing materials that are moisture and therefore mold formation sensitive. This is a big problem, given the potential for mold problems building like in 1 and 2 above.

With wet or humid soil on the exterior, concrete cannot dry to the outside. With the inclusion of a polyethylene vapour barrier on the inside, concrete is prevented from drying inwards as well. That leaves a sealed waterproof cavity containing untold thousands of litres of water along with moisture-sensitive and organic materials that are the perfect breeding ground for fungus and mold. Does this sound like a good idea to you?

What Building Science Corporation has to say about this type of basement wall assembly -

"The experience by the Building Science Consortium with these two approaches has been bad. The Building Science Consortium has concluded that these two approaches are unsuitable for use by the home building industry due to serious problems associated with mold, decay and odors. This is consistent with reports from Canada where basements are insulated in a similar manner (Fugler, 2002) and from other researchers in the United States, notably in Minnesota (Ellringer, 2002). Continued use of these approaches by the home building industry will likely lead to a disaster of unprecedented proportions"

Even if basement foundations were allowed to dry completely before interior finishing started and they included all the necessary waterproof membranes on the exterior, interior insulation means the temperature of the concrete will be determined by the temperature of the ground or air outside.

With some types of insulation this can allow warm, moist air to condense on the cold concrete. Having no insulation at all does not eliminate these issues; you are also at risk, just not to the same extent if you don't have moisture sensitive materials directly in harm's way.

For a basement to have any chance at doing what you want it to do without growing black stinky and unhealthy mold, it should be finished with respect to the conclusions of building scientists regarding moisture movement namely;

"Vapor barriers on basement insulation will rot your walls"

We put vapour barriers in basement wall assemblies to keep moisture from getting into them, as if they didn't already contain thousands of litres of water. Polyethylene won't keep foundations dry, they are already soaking wet. All it will do is prevent the thousands of liters of water that are already in the wall from drying safely to the inside, where it could easily be handled by a dehumidifier or by ventilation with an HRV or ERV System.

The only way walls below grade can possibly dry is to the inside. We have to stop trying to prevent that by wrapping them with an impervious layer of plastic. We also have to realize that building below grade is a different beast that building above grade, and to start respecting the laws of physics when we design, build and choose materials for basements especially in relation to the best insulation types to choose for basements.

Better basement insulation techniques:

The materials and design you choose are very important to prevent mold and should be appropriate for the environment they are destined to inhabit. Be very careful how and where you install wood and fiberglass insulation in basements (If you must), and be sure they won't see prolonged exposure to moisture or contact with humid surfaces if you don't want them to go moldy.

Spray polyurethane foam (SPUF):

When SPUF works out, it can be one of the better performing products in basement applications. Being sprayed directly onto concrete walls, it ensures an even and total protection. SPUF has a high R value per inch, acts as an air barrier and a vapour barrier. However, it has been known to shrink after application, leaving air gaps and a lack of thermal protection.

Another downside to the original SPUF is that some blowing agents have a high global warming potential (GWP). For this reason, we like to explore less harmful alternatives whenever possible - though *January 2018 update: new blowing agents for spray foam virtually eliminate green house gases, read more here.

Probably the most worrisome problem (as reported by a SPUF installer) is that there is a great temptation for installation contractors to tinker with the chemical mix a bit, giving it more volume with less material, which is more profitable for the installers. There are not a lot of reported cases of this, but when it goes wrong it goes very wrong. Personally, I wouldn't let someone spray foam in my house without some pretty good references that I followed up.

All that said, here's how to proceed if you plan to insulate a basement with SPUF:

- Frame a 2x4 stud wall at 24" centres leaving a gap of at least one inch between studs and concrete.

- Shim up bottom plates to allow for water to pass under in cases of mild flooding.

- Have foam sprayed against the concrete wall. The space left between concrete and studs is crucial to allow a seamless blanket of insulation to create an air and vapour barrier. Unprotected wood touching concrete will wick moisture and eventually rot. One inch of SPUF will solve your problems; four or 5 inches will reduce heat loss and save you money in the long run.

- Have insulation blown onto rim joists if it isn't already done.

- Foam must be covered by drywall for fire protection.

- Don't install an additional vapour barrier behind drywall; latex paint will act in this capacity.

There have been a few nightmare cases reported where a SPUF installation went very wrong and also where applying spray foam insulation apparently made homes uninhabitable or unable to get a mortgage. Given the fact that application involves a wet spray that hardens on surfaces, spray foam insulation is very difficult to remove too, so we hesitate to recommend using this type of insulation.

These reported cases are rare but on the increase, so if you are at all concerned, there are alternatives to spray foam for insulating basements listed below that work well in the battle against moldy basements.

EPS (Expanded Polystyrene), XPS (Extruded Polystyrene), Mineral wool:

SPUF is quite expensive; so rigid insulation panels and a 2x4 wall with batt insulation can be a much more affordable option - but you need to know the right techniques for a succesful and mold-free wall assembly for a basement application - read on!

Rigid insulation board against concrete adds R value, breaks the thermal bridge and raises the temperature of the stud wall, which helps prevent moist air from condensing. The stud wall allows for the installation of wiring, additional insulation and drywall.

Drywall should be attached directly to studs, latex paint will act as a vapour retarder slowing any outward moisture migration while also allowing walls to dry inwards.

You may hear that EPS is somewhat moisture permeable; this is true, but only slightly so and not enough to be a problem. According to Professor Straube, two inches of EPS has a perm rating in the range of 60-75 ng, or 1-1.25 US perms, which is right on the cusp of what is defined by building code as a suitable vapour barrier (60ng and under).

At that level of moisture permeability, an almost immeasurably small amount of moisture will be able to migrate into the wall, but with no interior vapour barrier it will pass through harmlessly. EPS, XPS and mineral wool are unharmed by moisture, and perhaps most importantly, EPS and XPS are unlikely to provide a breeding ground for mold.

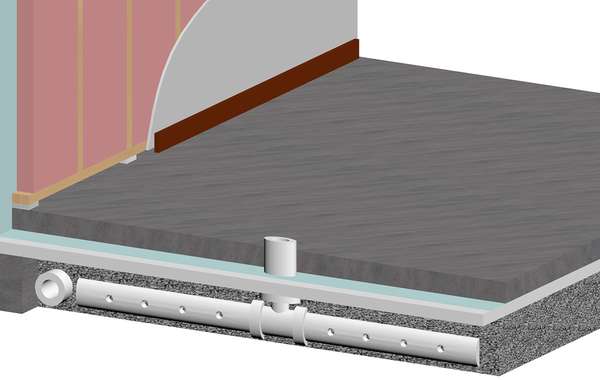

A polyethelene barrier can be included without causing harm (as seen below), as long as it is behind the stud wall, not in front. Specified correctly for basement Radon Mitigation, this will also act as a radon gas barrier to protect indoor air quality, and it will satisfy building inspectors who are not accustomed to seeing a wall without a vapour barrier and may not allow you to continue.

Note: the above diagram shows an ideal and complete basement renovation beginning with breaking and removing the existing concrete floor. Most older basements have very limited head room and owners are often reluctant to lower it even more by adding insulation to the floor. It also allows for the addition of a radon evacuation stack, which is the perforated tube and T-junction in this image.

By removing the concrete floor and maybe some of the dirt below it, you have room to insulate properly. Removing existing concrete is not as tough as it sounds - it can usually be smashed with a sledge hammer and removed in pieces. It does involve some hard work and heavy lifting, but the end result will not only be a more efficient and comfortable home, but a more valuable one at a time of resale and less likely to create the conditions that are best avoided - high humidity plus likely condensation points - both factors in producing a moldy, unhealthy basement.

The ideal basement wall assembly to prevent mold growth:

- Install two inches of rigid insulation board directly against concrete. It is easiest to attach it to the wall with a couple of concrete nails or even some adhesive while you frame walls.

- Frame an interior 2x4 stud wall at 24 inch centres, pressed tightly against the foam panels.

- Install mineral wool batts in the cavities. Mineral wool is unharmed by moisture, and if it gets wet it will retain its shape and R value when it dries; fiberglass is not so resilient.

- Lastly, install drywall and paint it with a latex paint only.

This technique of rigid and batt insulation may require a few more steps, but it can offer you a greater R value per dollar invested than SPUF and it allows you to do a lot more (or all) of the work yourself.

For reasons beyond just performance, we prefer mineral wool or EPS over XPS. XPS has a slightly higher R value per inch, but like SPUF, the blowing agents are exponentially more harmful, about 200 times more than EPS.

What else helps prevent mold growing in basements? Ventilation!

Another considerable improvement in keeping basements mold-free is to ensure adequate ventilation. Whilst cracking open a window if your basement has them is fine if the humidity conditions outside are favorable, that's pretty hard to judge; so a better alternative is to choose a good quality discounted HRV or ERV system with an automatic electronic humidity control.

Along with removing contaminants from the air, there are health consequences from having either too much or too little moisture in our homes. There are bacteria, viruses, moulds and mites that will show up on either end of the spectrum if your air is either too humid or too dry.

As the EPA say, somewhere in the range of 35 to 50% relative humidity is generally assumed to be the best for avoiding most health risks and irritants. It’s high enough that you won’t have cracked furniture, chapped lips or constant nose bleeds, and it’s not too damp for comfort, condensation or heat consumption issues.

If you're in an older home sat above a basement, don’t panic. What we write in these pages is meant to inspire ideas and solutions, not fear and anxiety. If you feel good, your basement smells good and your windows (and walls) aren’t dripping, relax!

However, if your basement has a certain musty smell, or telltale black mildew and mold marks in corners or behind furniture, for peace of mind consider buying a hydrometer to measure your indoor relative humidity, which will cost you maybe $20 to $30 at most hardware stores. If you have an issue, and the humidity levels are off the scale, then chances are you've got a moldy basement even if you can't see it yet...

Top tips for a healthy, mold-free and comfortable basements:

- Test for Radon & install Mitigation if called for - because it's better to be safe than sorry

- Renovate using the best practices for mold free basements as oulined above

- Ventilate using a HRV or ERV, because let's face it - fresh air improves any Man Cave!

Now you know more about why basements are moldy and how to avoid mold when finishing basements. Find more about resilient and durable home construction in the pages below and in the Ecohome Green Building Guide.

Find more about green home construction in the Ecohome Green Building Guide pages - also, learn more about the benefits of a free Ecohome Network Membership here. |

In the beginning of the article you say that basements should dry to the inside and later you explain how to insulate the basement from the inside by SPUF which "acts as an air barrier and a vapour barrier". Wouldn't that trap moisture in the basement? Thanks

I wonder why they haven't answered this...

Hi Adam and JC, sorry for the delay in responding, we miss comments on occasion. Let me make that a little more clear - that wall still does dry to the interior. When a stud wall is built against a foundation wall and then spray foamed, the foam will dry to the interior, as will the studs from their exposed surface. Once the foam has set there is no more source of moisture from the other side as the foam prevents any of the moisture in concrete from migrating inwards.

Is that the same with rigid EPS (white) boards along with mineral wool?

I've been going back and forth between Ecohome and GreenBuildingAdvisor. I have a 100 year old house with a concretefoundation and unfinished basement near Toronto. It has some water appearing on the perimeter between the slab and walls. Here are my thoughts: install an interior French drain with a T-pipe that attaches to a radon fan (depressurize under the slab, vent between the joists to the outside). The sump pump will have an air tight lid, the discharge pipe will have a check valve, and there will be concrete installed over the crushed stone over the drain.

On the outside, I'll do skirt insulation with a waterproof membrance as an underground roof to keep water away from the foundation and increase the soil temperate to eliminate the risk of free-thaw damage.

Additionally, I'd follow the advice in this article, which is to install 2" EPS, stud wall, rockwool batts, drywall, and latex paint. The basement has partially embedded joists so I will caulk around the joists and put expanding foam in the void between the joists to air seal that area. The exterior insulation will help but I think air sealing rather than insulating this area will decrease the chance of issues with joist rot or cold perimeter floors.

That's a big plan. What do you think? Do all of those pieces work together? Did I miss any important details?

Hello,

I wanted to install foam boards and my basement and frame against it. However, I have cast iron sewer line running against my basement wall... so while I can cut the foam board insulation around the pipe , I will not be able to frame directly against the foam boards. Is this a problem? Can there be a small gap between the foam board and the framing ?

Thanks