Is there anything I can do about a vapor barrier on the wrong side of a basement wall?

I have a problem with a basement that was finished about 1999. The house itself is from 1938 with a field stone foundation. When the finished the basement they put pt wood directly on the concrete, put R19 batts between the studs, and covered the whole thing with a poly vapor barrier and then drywall. So the vapor barrier seems to be on the wrong side to allow drying.

I had one corner where baseboard was showing signs of deterioration so I pulled that off and found that the baseplate (? whatever the studs are resting on) is rotted out down there. The studs seem fine apart from the lower inch or so. About six feet is completely gone in one direction from the corner. The other direction is deteriorated but not bad for about 3 feet. So far my plan is to replace the baseplate, repair the studs, put in rockwool for the last foot or so of insulation, put drywall back up and call it a day. Save money to redo the whole assembly.

My question is: Is there anything else I can do about that vapor barrier without tearing out the whole wall? I've read enough of the basement articles to know that on a new wall I should put a vapor barrier right against the foundation, then the wall assembly. Ideally with a perimeter drain as well. But this isn't new and that's not gonna happen for a while. Thanks!

Putting vapor barriers on the interior of a basement walls is probably the biggest mistake that is regularly made in the home construction industry and it is building up to eing a major catastrophe as homes like yours that were built about 20 years ago start to mature and show signs of what’s going on behind the walls. What you are seeing with your rotting sill plate is likely happening around the entire basement. You may have seen this page but others reading may not, but this article is about what is going on in your walls –

Why basement walls go moldy and how to build basement walls that will stay dry

At this point it sounds like the damage is done, but you may be able to buy yourself some time before doing a major renovation by letting it air out a little. Is the basement finished and furnished? I ask because the solutions aren’t particularly aesthetically appealing if it happens to be currently used as living space. I would cut full length strips of the drywall out every 3 or 4 feet and maybe as well as the poly vapor barrier, to let some moisture escape through those new vent holes. If walls are already rotted out and beyond repair, this may help a little bit or it may make no noticeable difference at all. Is it really humid and smelly to the point where you aren’t even using it as living space?

Eventually though, as you seem to know, you will need to do a full renovation and remove all the walls and do it properly.

It is currently being used as indoor living space. Primarily playroom for the toddlers where they can go nuts in the winter when it's well below freezing out. Overall, it only smells musty if the dehumidifier stops running for a couple days, and that seems to only be true in the summer. I only figured out this was happening because of deterioration on the trim piece in that corner. No other trim is showing signs of moisture. I had to pull off the trim on the side that is above ground (it's about 3/4 walkout height) and that one was fine. I guess the old fieldstone can dry to the outside there. Will putting in vent strips or the like cause a problem with heat loss? That R19 in the walls is, based on your articles, saving me some $. Long term I know I'll have to redo it, I just want to delay for a few years.

The insulation woudl be preventing some heat loss, but it doesn't work as well when its wet so it's probably not performing perfectly. So if anything letting it dry out would probably improve the performance a bit.

The only concern I would point out is mold and air quality, but if it isn't too severe and no one is experiencing any adverse effects then you probably can push it back a few years, and for sure keep the dehumidifier running.

Your foundation wouldn't really be drying to the outside though if its below grade. That's the problem with vapor barriers in basements, the industry seems to have forgotten that foundations are backfilled with dirt, and dirt is wet, so they simply can't dry to the exterior below grade.

I would make a few vent holes if you can, and keep running the dehumidifier and don't sweat it too much. As you said, you only just discovered it by chance, and millions of people have the exact same thing going on and don't even know it. So keep an eye on it, best of luck Iain!

Thanks!

Hi Mike and All!

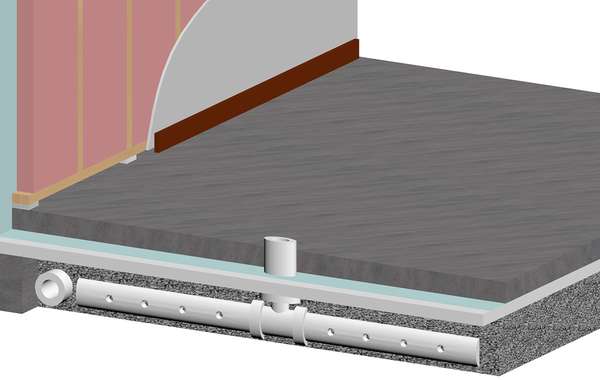

I was about to hang a nice custom shelf in the utility room until I noticed water coming behind drywall, which led me here. I, too, had fiberglass against the concrete, and then vapor barrier holding moisture in, and then drywall. I believe a bad window seal allowed water in during a summer storm and it could never dry out. I ripped the entire wall down and building new before I mount the shelves. I love ideas I've learned from your posts on here but wonder if someone could still help me with specific questions? Right now my plan is 2" rigid fiber board adhered to the concrete wall, then either a 2x4 wall with mineral wool or I might leave it and adhere a thinner 1x4 wall on their sides since I don't have much space and will be building over my sump pump.

Please and thanks so much!!

Hi Robbie,

1 - no you don't need those metal pins in the foundation so cut them off.

2 - 2 inches of EPS insulation is an effective vapor barrier, so no you don't need any additional protection, if you're going with only 1 inch then you might want to first install a 6-mil poly barrier.

3 - If I'm getting what you mean and the poly at the top of your wall is keeping moisture in the concrete, that's not a bad thing. Concrete is very porous so it will forever absorb moisture from the ground and deposit it into walls if allowed, or dry to the interior. Without being separated from the ground with a membrane your concrete will always be wet and that's no problem as long as you take steps (like the rigid foam or poly) to prevent your walls from being saturated with moisture.

Thank you thank you thank you!! I broke the pins off, doing 2" and no other barrier, and cutting the extra poly off and letting those top edges dry out a little more. I now suddenly found a leaky furnace vent pipe and have a rotted top sill plate. I'm carefully cutting and replacing a 3' chunk of it and will then finish the project. Thank you!

I just purchased a home with a crawl space basement. 80% of basement is a large piece of granite and only at the entrance of the basement, there is a small dirt area. The major problem of this house is the basement. Once you open the door, you breath in moldy air. The basement always feels damp. A couple of joists show sign of rot ( about 1/2"-1" hole if you poke with a screw driver in the section close to the entrance area joist and the black iron pipe is already rusted very bad.

Basement structural elements are posts on the exterior wall which supports the upper building walls. All basement ceiling seems to be sprayed with foam insulation by the previous home owner. Some 2x6 wall are either sprayed or has pink insulation for majority part. But due to the ledge in basement, there is no way to build a complete sealed exteriors wall. I see the gap between wall plate and ledge which are spray foam sealed for majority part. But still can see small area there is still gap.

My question is how do I apply moisture barrier in the basement? Should the 6mil or 10mil plastic sheeting apply to the ground or to the ceiling? Should I open some ventilation holes in the basement wall to let air flow? Should I close the vent during winter months.