Does strapping’s nailing jeopardize membrane integrity?

Does nailing battens on a ceiling or wall to create a service cavity creates significant leaks in a membrane to worry about? Or afterward stapling wires, screwing jonction boxes, etc. through the membrane...

[This is a single level construction in zone 6 where: – ceiling is a vented cathedral roof with R60 cellulose, over 1/2” Enermax (wood fiberboard with aluminium foil vapor barrier), double 1×3 strapping and v-groove pine planks. – walls are cedar siding, 1×3 strapping, Typar WRB, 1-1/2” wood fiberboard, R-20 hemp batt insulation, smart vapor retarder ProClima Intello, double 1×3 strapping and v-groove planks.

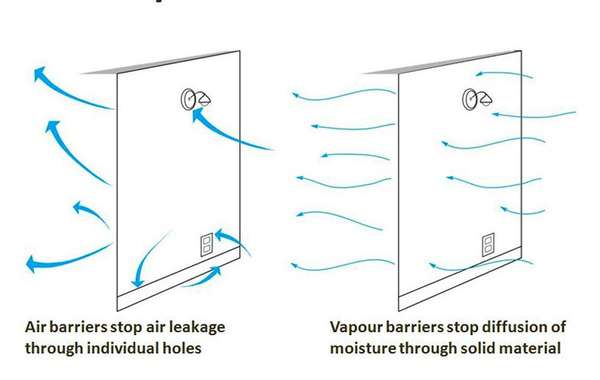

Putting nails through a weather barrier or vapor barrier to attach strapping will for sure create holes, but how much air leakage that leads to depends on a few factors. The membrane you choose would be a factor, so I would see this page first –

Choosing the right house wrap / WRB, which is best?

A peel and stick membrane that is glued directly to sheathing will give be the most resilient air barrier because it has substrate behind it, and the membrane can seal around any screws or nails to a certain extent. See your peel and stick air barrier membrane installation video here.

When you are attaching a loose WRB (weather resistive barrier), there is a lot more chance for nails and particularly staples, to leave bigger holes. And even the small amount of air pressure that it may be subject to can cause holes in a loose weather barrier to widen over time. So we prefer the peel and stick kind when possible.

With a loose barrier like the Typar weather barrier you mention, if you’re cautious with installation and not firing wildly with a nail gun or staple gun, that will help. You could also run a bead of acoustic seal along the center of the strapping where the nails will go so that it will plug any holes.

You have two another opportunities to make it airtight with the smart vapor retarder as well as the foil membrane, had you planned to tape either? Think of your air barrier as having multiple lines of defense, and every bit helps. The fact that you are choosing the Proclima Intello smart vapor retarder indicates to me that you have a pretty good idea of building science and the importance of an air barrier, so right off the batt I think you will do a good job because you know how important it is. Quality installation of any component of a wall system will make all the difference in durability and performance.

This page would be good to see also, about how to install siding so walls can dry. In there you will see some strapping details that will allow air and moisture to flow properly and to avoid moisture build up.

Thanks Mike,

To clarify, in my case Intello is only on the walls, and the foil-lined Enermax only on the cathedral ceiling. The Enermax panels are indeed taped at each joints and nails, and the Intello at each overlap (including at ceiling junction and concrete slab's vapor barrior). But I was worrying about the stappings added afterward and their nails, some that missed the stud or rafter, some that splitted the strapping. Same situation for the nails on the WRB side...

Hi Guy, yeah there will be a few missed nails on occasion. Saying some nails 'missed' the stud is past tense, so it sounds like it's already done? If that's the case, I'd suggest you just not lose sleep over it. Simply by this exchange I would be confident saying your house is likely much more airtight than most, so don't sweat it. if you are at the stage where the walls are strapped but not drywalled, if you want to find additional leaks you could do a blower door test, which depressurizes the home and helps you find air leaks as you can feel air coming in though them.

And this is speaking from an almost identical experience - on our Edelweiss House demonstration home we nailed 2x3's to the ceiling as strapping (to allow room for wiring and electical boxes without piercing the air barrier) and I had the same concerns. Ours was going for LEED Platinum so we had to have it extremely airtight, and during our blower door test we were able to find and seal dozens of tiny holes and cut the air change rate by close to half during that process.