What is the best way to insulate a 2x4 wall from the outside in a cold climate?

I have a 1960s home with 2x4 walls, vapor barrier behind drywall, fiberglass insulation, plywood cladding and siding. Located in Alberta, Canada.

i am planning on re-insultating and sealing from the outside.

trying to make sure the wall assembly will dry effectively.

i have identified at least 3 options, and i am unsure of best path to follow:

1. Remove existing plywood and cavity insulation, spray foam cavities from outside in, reinstall plywood (might be some air gaps behind plywood), add tyvek drainwrap wrb, then add 2" polyiso enerair, 1" strapping, siding.

2. Remove existing plywood and cavity insulation AND existing poly vapor barrier. Install rockwool batt insulation with NO vapor barrier (to allow drying inwards), reinstall plywood , install peel and stick wrb/air seal, then add 4" comfortboard rockwool, then 1" strapping, siding.

3. Leave existing wall assembly alone, install peel and stick wrb, then add 4" comfortboard, then 1" strapping, siding.

i want to improve air sealing and thermal performance of the walls, but I don't want to create a moisture trap. I have seen a few people add 2" ridgid foam to the outside, and think that will have moisture issues in between inner poly vapor barrier and the unbreathable foam.

any suggestions or links to previous similar questions appreciated.

Energy efficiency upgrades for walls are best to do from the outside, so I think you are taking the right approach. If you haven’t seen it already this is a good starting page –

How to insulate walls in old homes from the exterior

How insulating stone walls can boost your home's energy performance

That will give you a good idea of the science behind it, but you may have read that or a comparable page, as you seem to have a good sense of the building science issues you are facing. And from your suggestions I think you may already know about the 2/3rds rule for insulation, which is covered in that article. Here is some feedback on the wall systems you propose :

Option 1 – No one here is a big fan of spray from for a few reasons, you can see the downsides of spray foam insulation here. But what you propose would work, only I wouldn’t go with Polyiso also for a few reasons, see here about choosing the right rigid insulation panels. If you did that you could use normal EPS or rigid mineral wool which would be an improvement.

Option 2 – Rockwool in cavities and exterior is a very safe option, but I would keep the poly in the walls unless you had another vapour retarder solution in mind like a vapour barrier paint. Poly only becomes a problem in summers in very hot regions when people put the AC at really low temperatures. See here about the problem with poly vapour barriers and air conditioners.

Option 3 – that’s a pretty good option as 4 inches of mineral wool will let moisture escape. That said – adding a peel and stick membrane is going to act as a vapour retarder, so doing 6 inches if you are able would be pretty much bang on the 2/3rds rule I referenced (keeping 2/3rds of the insulation outside of the vapour control layer).

The only issue with doing 4 or 6 inches and strapping, is that the screws start to get long in order to attach them. Anything over 6 inches starts to get really expensive per screw, and you also have thermal bridging issues. So you may want to look into fasterner options. Cascadia clips is one such way.

And another option is Thermal Wall insulation panels from Legalett which have metal rails embedded in the middle of the foam panel, so you attach them with short screws to the wall, then attach the strapping with short screws to the same rail. That would solve your thermal bridge issue, the long screw cost issue, and with 6 inches you can leave the batts in the cavities and have just about 2/3rds on the outside with a total R value of about R37.

Thanks.

great advice!

I am still a little confused about the building science with regards to vapor.

in this cold climate region, it is pretty much standard building practice for many years to place a poly vapor behind the drywall on the warm side of the insulation. This Vapor barrier also acts as an air barrier I think. This Vapor barrier is important in the winter when indoor humidity much higher than outdoor humidity to reduce vapor penetration into the wall cavity, and subsequent freezing on the inside of the plywood sheathing.

I think the building science says it is better to place the water, air and Vapor control layers at 2/3 of the thermal control layer.

my confusion is that if I place external insulation on the outside of the wall, warming up the sheathing, and I have a poly vapor barrier at the drywall, if any water or vapor gets in the wall, then it has to dry outwards.

but if I take out the existing poly layer at the drywall, the wall could also dry inwards, as well as outward. But taking out the poly goes against common building practices in this area as vapor can flow freely between the outside and inside.

I understand in new construction, you can put a smart vapor barrier behind the drywall instead of the standard poly, and that is good.

But I'm trying to make wall better without disturbing the interior drywall. I apologize for being confused.

I think you actually have a pretty good understanding of the science Kevin.

Yes, for cold climates you need a VB on the interior for all the reasons you say.

And yes, if you stick insulation on the exterior it can cause issues, so good that you are aware because doing renos afterwards severely limits options compared to new builds. So perhaps I can make that more clear –

If you are going to strip the exterior sheathing and insulation to expose the wall all the way in to the vapor barrier and drywall, they what you plan to do should decide if you leave the poly or not. When I said leave it, that was option 2 I with the mineral wool, and you do need an interior vapor barrier.

If you put spray then the foam itself becomes the vapor barrier. Stripping all the insulation and putting batts then 6 inches

Yes, the perfect spot for a vapor barrier is with 2/3rds of the insulation on the cold side of it, but that is high end building and virtually never happens with standard tract homes, and your options are limited with a reno that is limited in scope such as what you are doing. so just keep that in mind and don’t stress too much. It is highly unlikely that the interior vapor barrier is done so well it that it will trap moisture for an eternity, so I wouldn’t worry too much.

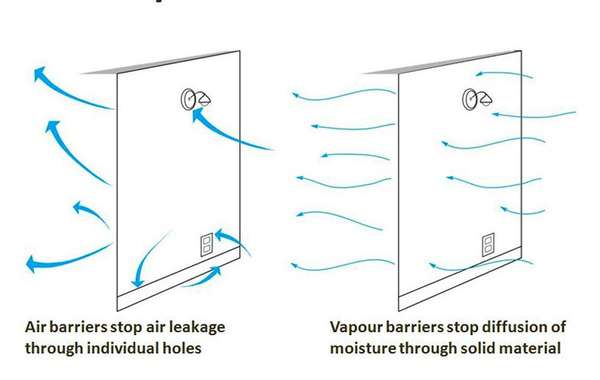

Air / vapor barriers – yes, most of the time the poly barrier is also expected to be the air barrier, but it really is a different role. you can read more here about the difference between air barriers and vapor barriers.