Siding installation

The walls of your home are an environmental separator. Their job is to keep the inside in and the outside out. Exterior cladding or siding is your first line of defense against weather elements, and its job is to allow interior control layers (ie. the building envelope) to do their jobs without being assaulted by wind, precipitation and UV rays.

Walls in heating/cooling climates like Canada need to be designed to dry during all seasons, not just winter, which is how we most often build them now.

Moisture will always flow from areas of high concentration to low, and the side of the wall those different conditions are on will reverse between seasons due to insulation and/or air conditioning. In winter it is cold and dry outside, in summer it is hot and humid outside, hence the need to dry in both directions.

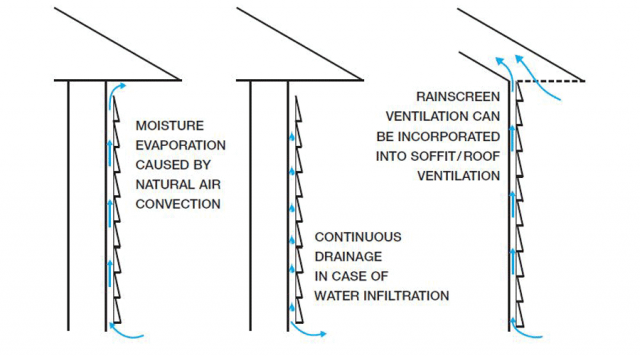

In order for something to dry, an exchange of energy needs to take place. When we heat a house, it dries outwards, when we cool a house, it dries inwards (or at least it should - depending if you have a vapor barrier). A well-ventilated air space between sheathing and cladding is an important part of the strategy needed to allow walls to shed moisture in all seasons and conditions.

Drainage planes (building paper, house wrap, etc.) allow any moisture that does accumulate behind siding a chance to drain away harmlessly. The air space between siding and sheathing should also allow humid air to escape. In order for both of these actions to take place, when siding is installed correctly there needs to be a continuous space behind siding where water can drain and air can flow.

Common siding installation mistakes to avoid:

- Caulking the top cladding board to trim boards: This creates a dead end that traps humidity in walls behind siding.

- Cutting boards short and relying on caulking to fill the gap: Caulking will eventually fail, letting water in but also potentially keeping it in. Boards are best installed tight, a certain amount of shrinking will occur but any water that gets in will be able to dry. Be sure to seal all cut ends with paint.

- Installing horizontal furring to attach siding: If your siding requires horizontal furring (such as board and batten), install a first layer of vertical furring to allow a drainage cavity, then a second layer. Horizontal furring strips can stop air flow and prevent water from draining out. Diagonally installed furring is an option that can also work without needing a second layer.

- Double furring at the corners: corners are often needlessly fortified with furring strips (or strapping), where they should ideally be left open and able to dry. If water is going to leak into walls it will be at joints and junctions like corners.

|

|

Air spaces behind siding allows water to drain and moisture to escape. © Ecohome

|

How much of an air space is needed behind cladding?

The air space between cladding and sheathing doesn't need to be great but it needs to allow continuous drainage without creating pockets where water can sit trapped inside wall assemblies, which is referred to as perched water. It can then sit there and soak into your building materials until it gets filled up again durinfg the next rain.

Correctly installed siding should also allow air to flow through from top to bottom, taking advantage of natural convection to remove moisture.

1x4 and 1x3 furring are most commonly used as they are easily available and affordable, but that doesn't mean you can't find even cheaper alternatives that could save some wood and maybe some money for someone that likes a DIY project. If you have enough material to meet your needs, you could use old flooring, even old plywood ripped into strips on a table saw.

An air space of even 1/8th of an inch will do the job, so what you use as furring is really only a spacer and isn't too important as long as your siding can grab it, or grab the sheathing behind with longer nails. The most important thing is that the material be consistent in size to avoid walls looking warped.

|

|

Air space behind correctly installed siding for drying and drainage © Ecohome

|

Can you keep water and moisture out of walls?

Some of the things we do that were originally intended to keep walls dry (polyethylene vapor barriers, for example) are now more commonly keeping them wet. We have grown to rely heavily on caulking - often referred to as 'liquid carpenter' - as a a cure-all for every mistake, and to allow for quicker installation by cutting less precisely.

Caulking on poorly installed siding always looks great at first, but it will break down over time (more quickly on south facing walls), and at some point may actually hold water in instead of keeping it out.

Setting out on a mission to stop all water and moisture from ever getting into your walls will more likely ensure that they will get wet and stay wet. The walls that will last the longest are the ones that have been designed to realistically manage moisture and dry out, not those designed to achieve the unachievable. With a few material exceptions of course, for the most part it is okay for walls to get a litte wet as long as they can also dry out.

An analogy on this topic credited to Professor John Straube of the University of Waterloo may help you accept this defeat graciously: with a price tag of several billion dollars, a Trident ballistic nuclear missile submarine is one of the most sophisticated and expensive machines ever made. With unlimited funds and access to the most advanced technologies, in the end they still assume water will leak in and they install a pump. Conclusion: you can't build something that doesn't leak, so focus on making sure it can dry when it does.

Now you know all about how to install siding so walls can dry. Learn more about best practices for energy efficient and durable home construction and renovations in these pages:Frost in attics: what causes attic ice? How to fix it?House air tightness - why balancing air pressure is essentialTop tips for getting a house ready for winterWhat is the best insulation for a home?Why roofs need to be ventilated and how to ventilate a roof properlyFind more about green home construction in the Ecohome Green Building Guide pages - also, learn more about the benefits of a free Ecohome Network Membership here. |

Hey Mike,

Thanks for the article. What are your thoughts on this statement?

"Because it already has an air space behind it, vinyl siding does not require a rainscreen installation unless it is installed on top of rigid foam that is more than 2 inches thick, in which case it should be installed over vertical furring strips.

If your walls are sheathed with rigid foam, most types of siding — especially wood sidings — require vertical furring strips. If you’re installing vinyl siding over thin (2 inches or less) rigid foam, you can probably skip the furring strips."

Thanks for your video. I am planning to build a wworkshop (Ottawa, Canada area) and I wonder how do you cover the 8 inches of Roxul insulation that you put around the slab so that water do not penetrate inside (rain or snow melt)?

Hi Michel, if its not too late drop me a message at [email protected] in case you have other questions, we're in the same city. There is a flashing behind the siding that directs any water over top of the exterior insulation and to the cement board. We also used Roxul for skirt insulation, their engineers weren't concerned with it as is, but on the small chance that it got wet and then we had a flash freeze, we covered it with leftover 6 and 10 mil poly. Roxul won't absorb moisture from below, so as long as you prevent wetting from above it works great. And in the event that it does get wet, it dries easily, and once it does there is no detrimental effect on performance.

I just read the article you posted above and here is a newer one from that same site...do you have any more current sources against vinyl? I am looking into adding insullation to my home and will have to use some type of siding on it after.

As a rule we don't keep links in comments, that was an oversight so I've removed it. As for the article you included promoting vinyl siding as a 'green' option, I googled the author of that article and I learned that he is a consultant with the Vinyl Siding Institute, meaning he makes a living by promoting vinyl siding.

Every harmful industrial sector like oil, fracking, tobacco, and in our case questionable building products, have lobbyists that get paid hansomly to talk it up. And, as we find regularly on our site, industry reps come on to promote their own products in backhanded ways, often just by asking questions about their own products to start a discussion. The reason I mention that, is that in the authors bio in the article you linked he calls himself an author and builder, but makes no mention of the fact that he represents the industry he is writing about as if it is done from an unbiased position, which it is not.

The internet is a sketchy place, so to avoid getting promotional info from industry representatives you can google how something is made and follow that lead to see its human health and ecological impacts, then cross reference that with other sources to be confident its fairly accurate. In this case, unless something has changed, vinyl siding is made of polyvinyl chloride (PVC) resin, which is highly toxic to humans and pollutes our air and waterways.

If you find out its truly not harmful then please by let us know what you've discovered and we will happily update the article. We have no vested interest in steering anyone away from a product due to providing incorrect information, and we aren't perfect, but our motive is to provide our readers with as information that is unbias and accurate. We have no ulterior motive to prevent people from using vinyl beyond what is stated above, but the author of that article promoting vinyl siding DOES have a motive to hide the true ecological cost of the product he sells in order to get you to buy it.

Thanks for taking the time to ask about that Erin. All siding will have an ecological footprint of some kind, there is no way around that, we just look for the ones that are least harmful and most durable.

I like the analogy of the submarine and keeping water out of a house! I'm wondering how to allow an air space between the sheeting and the siding while not allowing pest (more specificaly mices) from entering that air space? I can imagine them climbing up the exterior of the foundation and entering that lower "vent".

Hi Jean-Michel

One technique is to staple a metal screen to the sheathing right at the bottom before the strapping, then fold it up and staple it to the exterior face of the strapping. This works fine for insects, though mice may have better luck getting past it. There are also dedicated plastic or metal products to serve exactly that purpose. Off the top of my head one brand I can think of is called Coravent.