Current rigid foam insulation panel choices

It would probably not come as a surprise to many people to hear that fiberglass insulation and rigid foam boards are the ones most available in todays insulation market; you can see that walking past any home building or renovation project, or simply as you walk through Home Depot or Lowes looking to inspire a Green home renovation project.

Given the increased pollution we are exposed to in our daily lives, more people all the time are developing respiratory illnesses. Cases of chemical sensitivities and asthma rates among children have skyrocketed in recent decades. So, the more non-toxic building materials that hit the market, the safer our indoor air quality becomes. Foam insulation boards such as EPS (expanded Polystyrene, probably the least problematic and the greenest foam insulation), XPS (extruded Polystyrene) and Polyisocyanurate dominate the market, and while some are better than others, these are all petroleum-based insulation boards that can potentially have an impact on human health as they can off-gas into homes.

Natural insulation batts and boards made from renewable natural resources (such as cellulose and hemp insulation) on the other hand, help preserve the natural environment while at the same time facilitating healthy indoor environments for families. As concluded recently in our article about Earth Day, "now’s the time to think, investigate, make better choices, buy better products – each and every day. Because if Governments and Industrialists won’t listen to the Planet, they are proven to listen to our Money." So with this in mind, it's time to consider some alternatives for rigid panel insulation products.

Natural "Green" rigid panel insulation:

There are many types of insulation arriving on the market in both batt insulation form as well as rigid insulation boards that are alternatives to what you can find at local building supply stores.

As homeowners become more concerned about climate change and their own carbon footprint they are looking towards Green Building techniques and the better manufacturers are responding by providing more sustainable building materials that offer a reduced environmental impact while at the same time enabling us to build healthier homes. If the market for Green Building Products exists & grows, then manufacturers including the large industrialists will cater to that market.

One such product that has us really excited, because it's looking like a "game-changer" though it is still in the research stage and not yet commercially available, deserves of a shout out we reckon - which is what prompted this article. Researchers at Washington state University have developed a cellulose insulation panel that one day we hope will replace foam as a standard building insulation. And better still is when the natural alternative for rigid foam insulation boards is a high-performance panel with a higher R-value than current rigid insulation panels such as EPS, XPS and Styrofoam.

Cellulose insulation is not new to the contruction industry, loose-blown cellulose has long been used as attic insulation, and Dense-packed cellulose insulation is an excellent way to insulate walls. Our current demonstration house will be a pre-fab wall system insulated with cellulose. Since celluose is the main component of trees and plants, it is the most abundant bio-based raw material in the world.

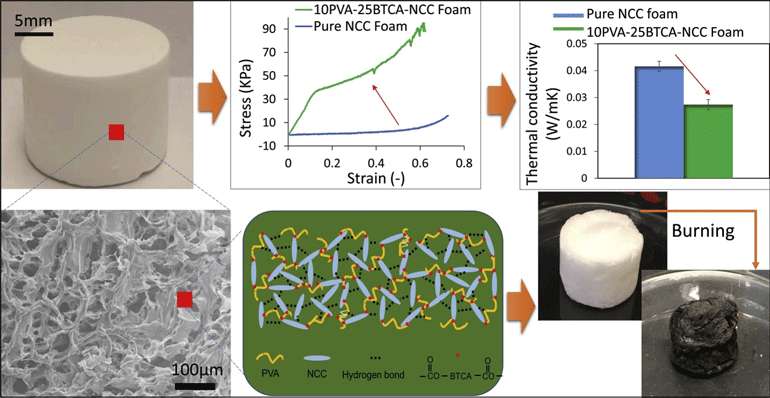

This innovative new insulation option that interests us so much uses the cellulose nanocrystals (CNC) that are extracted from cellulose fibers and fibrils, through acid hydrolysis.

This chemical process dissolves the bonds of amorphous chains of cellulosic fibers and releases CNCs, making them adaptable to various applications. These nanocrystals generally have excellent reinforcing properties thanks to their microstructures and their high-crystallinity.

In itself, nanocrystals are not innovative; they have long been used for electronic devices, cement, paper, coatings and paints. But being used to develop a natural insulation is entirely new, and a possible game-changer in the field of sustainable housing.

The crystals are mixed with wood pulp and polyvinyl alcohol, a polymer that binds to the crystals to form a type of elastic foam. And the result could soon be a Green home rigid foam insulation panel product with a very environmentally-responsible life- cycle, and excellent thermal performance that might spell the end of styrofoam in new home construction and renovation.

Environmental performance:

This new Cellulose rigid insulation panel is a particularly ‘green insulation’ because it uses water-based solvents and eliminates the harmful blowing agents with high GHGs (green house gases) that are found in most rigid foam panels.

Another ecological advantage is that it breaks down easily at the end of life, compared to foam board insulation panels that do not degrade naturally.

A high-performance rigid insulation board:

Aside from the health and environmental benefits this natural insulation can provide, it even surpasses the R-value of polystyrene foam because the thermal conductivity is very low at 0.027 W / mK. For comparison, polyurethane foams have a thermal conductivity of 0.022 to 0.028, and that of wood fiber insulation is 0.040 w / mK.

Preliminary research is also showing these lightweight CNC foam boards can withstand up to 200 times their weight without changing shape, which is encouraging because it means that they may also be able to replace high-density foam boards in some applications.

Our mission here at ecoHOME is to promote more sustainable building practices and the use of environmentally-responsible building products wherever possible, so this is exactly the kind of advance we are thrilled to report. We look forward to a day when we can list local providers of natural insulation products such as this, so stay tuned!

Take a look at the importance of rigid insulation panels in a LEED Platinum certified wall assembly here:

For more information or to contact the researchers at WSU - Especially if you're a manufacturer of rigid foam insulation wanting to produce a more environmentally friendly insulation product - please see here

Now you know more about cellulose insulation. Find more pages about sustainable construction below and in the Ecohome Green Building Guide pages.

Find more about green home construction and discover the benefits of a free Ecohome Network Membership here. |

Hi, you say that this cellulose board insulation has a thermal conductivity of 0.027 W/mK. When I convert this to R-value, I get a metric RSI value of 0.941 per inch or an imperial R-value of R5.34 per inch. Is that correct?