Radon gas in crawlspaces and basements - why is it a problem?

Radon gas was not high on the radar of builders and home owners over the last few decades, but as it is the second leading cause of lung cancer (after smoking) in the USA & Canada, it is quickly becoming a household term. Many newer homes will have radon barriers and vents but the question remains of how to deal with high levels of radon in existing homes with no mitigation system in place.

Below we outline radon mitigation solutions on a case-by-case basis, with different options available for different foundation and basement situations.

If you just found out you have high radon levels in your home, or you've looked at a an updated radon map that shows your state or region as being at risk of high radon levels, don’t panic; there is virtually always a way to fix radon gas levels in a home - I should know, my house was tested to have high radon levels, and after radon mitigation was installed and we re-tested for radon, I now know we can live safely - so radon mitigation works!

First step, find out if you have a radon gas problem by having the air in your home tested. A radon testing kit is not very expensive and should be available through your municipality, state, or via a reputable radon testing kit brand online. You usually need to put a radon testing unit on each floor of your house and forget about it for a few months; then send it to the lab to learn the results.

Testing is better done in winter when windows are closed to get an accurate reading. Normal activity like doing laundry with a dryer vented to the exterior and running ventilation equipment is to be expected, so you don’t need to change your normal behavior when testing a home for radon.

If you know or suspect that your home is "at risk" for radon, then consider installing a continuous SMART Radon monitoring system with alarm via a dedicated App - these cost a little more but give added peace of mind and radon gas levels in the home can be tracked. Click on the image below to see one option we like, or compare and get pricing on Radon Monitoring systems here.

If you get a high radon reading in the air, the next logical step is to determine the source, so first check your water for radon to see if that is the problem; read more here.

In high radon risk areas, new homes often have ‘passive’ radon mitigation systems installed when they were built (a simple 4 inch pipe from below the slab to the exterior), though they have limited effectiveness as there is rarely enough stack pressure to draw up radon gas from the soil. They are still good to have, mostly because they can be adapted to include a fan to draw air if radon levels in the home turn out to be high.

Background levels of radon are present everywhere and are usually so low that there is no way to know ahead of breaking ground if a building site will lead to a home with unsafe radon levels. And as almost all homes will have at least some radon present, there is no reason not to take the basic steps in the beginning to avoid a harder problem to solve in the future. Having said that, basements are potentially more prone to radon gas issues, so that's another of the reasons to choose a slab-on-grade instead of a basement.

|

|

Active radon stack installation © Radon Works

|

Radon exhaust stacks - placement to avoid freezing in cold climates

Radon stacks are often brought up through the walls and vented out through the roof like a plumbing stack. The intention of that design is to keep it far enough from open windows to prevent the radon gas from re-entering the home, but that is unnecessary and can work against you.

The air below your slab is potentially very humid, and in cold weather it's warmer than the outside air. As a radon mitigation system can draw up to 2 litres of water a day through the exhaust stack, in colder climates this warm, moist air often condenses in the cold top of the radon stack and leads to freezing in winter as water vapour can crystallize in the exposed length of pipe extending from the roof and plug the radon stack completely.

|

|

Radon vent installation at low level © Radon Works

|

Preferably, if in a cold climate zone you would direct the exhaust vent from your radon stack straight out through the rim joist (as seen in the adjacent images), and there are several benefits to this location for all climate zones – it is a quicker install with less materials required, you avoid having to puncture your roofing materials and risk water leaks, and only a couple of inches of pipe is exposed to low winter temperatures if you're in a cold climate zone instead of a taller roof stack, so you greatly reduce the risk of freezing and getting the radon stack blocked up. It is also easier to throw a quick eyeball on a vent at ground level to check for freezing rather than getting up on your roof in winter, and very much easier to unfreeze your radon stack exhaust if you need to. Check pricing for Radon Ventilation fans here.

The location of radon exhaust vents can follow the Building Code requirements for venting combustion appliances, which is to keep them 3 feet from operable windows. Keep it further away if you can, but there is enough dilution of air over just a few feet to prevent any noticeable amount of radon from re-entering the home. And be mindful to locate it at least that same distance away from an HRV or ERV fresh air intake or even a basic bathroom or kitchen fan outlet - because when they are off, they could backfeed radon into your home if the conduit runs down into a basement - which would be bad.

Before starting radon mitigation in a crawlspace or basement:

Here's a thing, if you're about to install radon mitigation in a crawlspace or basement because your radon levels are above recommended levels, then the first step to starting the work and installing a radon barrier is to ventilate your work area. Open windows, put in a temporary low level inlet that goes outside at least 5 feet away from the window and turn on the fan for a couple of hours before you go working down there. Safety first, once you know there's an issue with radon in your home, avoiding breathing it as much as possible is a sensible precaution. If you have mold down in your crawlspace or basement too, wear a mask and take this into account in specifying your radon mitigation solution. Preventing mold when finishing a basement is possible, read here to find out how.

Radon in crawlspace floors that won’t be insulated:

A radon barrier needs to be installed to seal off the ground from the air in the crawlspace. A DIY radon mitigation solution for a crawlspace is to use a standard 6 mil polyethylene vapour barrier, which works, but contractors may be required by law to use a fire-rated membrane. The membrane itself is not impermeable to radon, but radon will take the easiest route, so as long as it is an active system where air is drawn by a fan from under the radon barrier, the results are usually quite effective. For extremely high levels and to ensure that your radon mitigation is dealt with once and for all, you may consider upgrading to a radon membrane that is tested impermeable to radon to be certain of satisfactory results from your hard work.

The radon gas membrane needs to be sealed to the exterior wall (higher up the wall is better if it’s below grade) and all penetrations from plumbing or structural supports need to be well-sealed, including the intake that will pull the radon from below the membrane and exhaust the gas outside.

Radon in crawlspaces that will be insulated:

The most effective technique for insulating crawlspaces and stopping radon ingress is eco-friendly sprayfoam applied on the ground and walls; for more details see how to insulate a crawlspace properly page here. To install a radon evacuation stack along with spray foam, there must be some medium in which the air and radon can move around below the foam. A layer of crushed stone will do the job as long as the intake is in the stone and not blocked by the foam. Spray foam will go on top of the stone and seal around the stack.

If getting a 4 inch-layer of clear stone into your crawlspace is not a viable option, there still needs to be a consistent separation between the ground and the radon barrier to allow radon to move freely below. This can be done by installing a dimpled membrane over top of the dirt, or another such suitable product.

If your crawlspace floor is flat, another option is to use a radon resistant ridged layer of XPS but be sure to carefully tape seams that allows air movement below. This will give you a bit more thermal protection, and will be air-sealed by the spray foam on top. By doing this, you will either be able to use a bit less spray foam or you will have a higher R value and more efficient thermal barrier.

Radon mitigation in finished basements:

If you have a finished basement and have discovered you have high levels of radon, don’t panic, there are effective and affordable options.

The easiest and most affordable option is sub-slab depressurization. Most newer homes would have a vapour barrier below the slab, though likely not well-sealed. Some homes will have none, but in either case, concrete in fairly good condition should provide enough of an air barrier to contain radon below it.

A contractor will drill two small test holes in the concrete floor on opposite sides of the basement, then install a vacuum in one and measure air flow with the other. If there is sufficient air movement below the slab, then a radon evacuation stack can be installed with a fan that exhausts to the exterior.

Rob Mahoney of Radon Works in the National Capital Region is a radon mitigation specialist who has had great success with this technique.

“We have taken finished basements with radon levels in the thousands of becquerels and brought them down below a hundred using sub-slab depressurization”, says Mahoney.

Dedicated HRV for radon removal: if testing shows that removing radon from below the existing slab will not be successful, an HRV unit (heat recovery ventilator) or ERV unit (energy recovery ventilator) dedicated to the basement can be very effective.

There is a continuous radon monitor called a Radostat that controls ventilation equipment by activating it when radon levels reach a peak 150 Bq. The HRV will kick in to high speed, and once levels have dropped to a safe level, the Radostat returns the HRV to its normal operating setting, and leaves the basement pressurized, which will reduce the amount of radon that can escape from the ground below.

Radon mitigation in unfinished basements:

The dedicated HRV system mentioned above is also an option for removing radon gas from unfinished basements, as is sub-slab depressurization. If you have extremely high levels and the HRV isn’t sufficient and you also are not able to do sub-slab depressurization, you can pour an additional concrete slab on top of the existing floor or even consider a sidewall mounted self contained radon removal system.

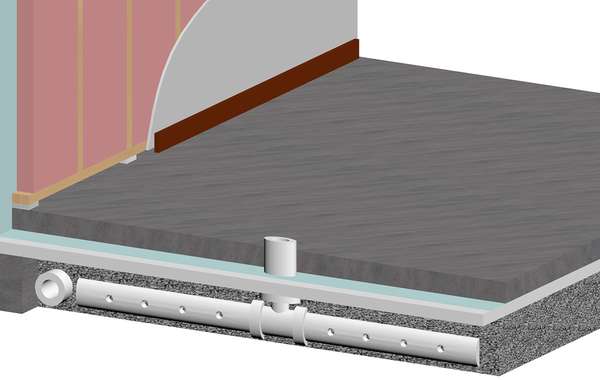

The intention for pouring an additional slab is to create an air-sealed cavity where radon can collect and be removed. This can be done with a ridged layer of EPS insulation with voids underneath where air can circulate. A 5 inch hole is cut in the EPS layer where a flange and radon stack are installed. Once it is all sealed, a new layer of concrete is poured on top.

To use the rigid sheets of insulation you would need a flat surface, so along with existing basement floors, this is possible in a crawlspace also if it is flat enough - though very few are.

Air sealing between floors to stop radon:

If you have extremely high levels of radon, the Radostat and HRV option may work well, but might not bring you to completely safe levels. Due to the stack effect of warm air rising, basement air will always find its way to upper floors to balance pressure as warm air escapes through leaks at the higher points of your house.

In such a case, you may wish to create an air seal between the basement and upper floors. Very few membranes will actually block the passage of radon; one that does is available here, a membrane that can be installed either under slabs or in this case, on the ceiling of the basement to separate those environments.

This will require meticulous attention to detail when sealing opening, but it can be a cheaper alternative to pouring a new concrete floor. We would also always recommend fitting a radon monitoring device or system to make extra certain no taped seams have come apart.

A ceiling membrane is a solution that should be used in conjunction with the HRV, so radon-rich air will not contaminate the upper living floors. The dangers from radon gas are from long-term exposure, so as long as you don’t use your basement as living space, going down to put on a load of laundry in a basement with higher levels will not cause you to drop dead on the spot; you just don’t want to live in it constantly.

Important to remember to stop radon ingress:

- Keep your HRV air intake clean! Blocked air intakes can depressurize the basement and cause a dramatic increase in radon levels by drawing it out of the soil.

- Sump pumps do not always have airtight lids, so be sure yours does or you will impede the system from doing its job properly.

- Radon gas in air is measured in becquerels per cubic meter (Bq/m3) in Canada, and Health Canada recommends taking steps to mitigate radon in homes when levels exceed 200 Bq/m3 . Radon test results in the USA may be reported in three different measures – picocuries (pCi/l), Working Levels (WL) and bequerels (bq). If your test result is in pCi/L, EPA recommends you fix your home if the radon level is 4 pCi/L or higher. If the test result is in WL, EPA recommends you fix your home if the working level is 0.016 WL or higher. Some states require WL results to be converted to pCi/L to minimize confusion. While not commonly used in the United States, any radon level at or above 0.148 bq should be reduced - pointing out that the EPA recommendations are lower than those in Canada. Also interesting or potentially worrying to note is that the World Health Organization WHO sponsored International Basic Safety Standards (2014) and the IAEA Safety guide on radon (2014) recommended annual average concentration reference level is 100 Bq/m3 - half the Health Canada recommendations. As the WHO puts it: "The lower the radon concentration in a home, the lower the risk of lung cancer as there is no known threshold below which radon exposure carries no risk."

The radon mitigation techniques discussed here are intended to give homeowners an idea of the types of solutions that are available for reducing radon levels in homes, they are not intended as a DIY guide. Radon contamination in homes is a serious health concern and is best handled by an experienced professional who can guarantee results.

“There are countless air sealing products available on the market, you just need to know which ones to use and how to use them effectively. There is always a solution for reducing radon levels; you just may need to be creative about it. The worst case we ever found was a home with a reading of 20,000 Bq/m3 and we were able to bring it down to under 70.” – Rob Mahoney.

Now you know the importance of keeping radon out of homes. learn more about home air quality and all you need to know about sustainable home building in the pages below and the Ecohome Green Building Guide.

Find more about green home construction and reap the benefits of a free Ecohome Network Membership here! |

Rob Mahoney is a radon mitigation specialist in the National Capital Region and sits on many advisory boards including the Canadian Association of Radon Scientists and Technologists, Canadian National Radon Proficiency Program, Canadian General Standards Board and CGA Standards (Compressed Gas Association). He worked with the CHMC on a radon prevention pilot program and helped bring radon prevention into building codes. A big thanks to Rob for his technical guidance with this page. To learn more about radon prevention measures, visit his website radonworks.ca.

Comments (0)

Sign Up to Comment